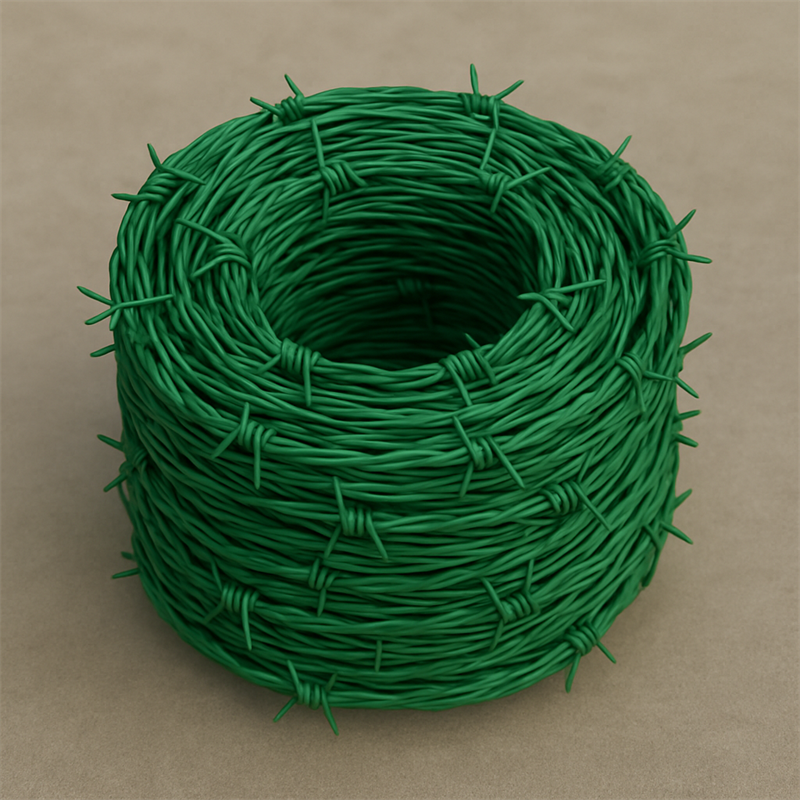

High tensile steel barbed wire

- Barbed Distance: 3 inches

- Barb Length: 10 mm

- Coil Outside Diameter: 450 mm

- Color Options: White, Green

- Transport Package: Nude Packing

- Specification (Wire Diameter): 1.8 mm / 2.8 mm

- Origin: China

- HS Code: 73130000

- Production Capacity: 500 tons per day

- Price Range: $550 – $890 per ton

Category:Barbed Wire, Product

Introduction

High tensile steel barbed wire is a premium fencing material designed for high-strength applications. Unlike standard low-carbon wire, it maintains tension over longer spans, resists sagging, and holds up against environmental and mechanical stress. This makes it a top choice for agriculture, industrial perimeters, military zones, and critical infrastructure protection where failure is not an option.

🧪 Technical Specifications

🔹 High Tensile Line Wire

- Material: Galvanized high tensile steel

- Diameter: 3.7 mm ± 0.05 mm

- Tensile Strength: 1235 N/mm²

- Galvanization Coating: 275 g/m² (hot-dipped)

- Coil Diameter: 1000 mm (standard)

This line wire forms the backbone of the fence, designed to maintain straightness and resist deformation under pressure from livestock or intruders.

🔸 Low Carbon Barbing Wire

- Material: Galvanized low carbon steel

- Diameter: 2.5 mm ± 0.05 mm

- Tensile Strength: 350 N/mm²

- Galvanization Coating: 240 g/m²

- Barb Length: 13–20 mm

- Barb Spacing: 60 mm ± 16 mm

The barbing wire is twisted around the main strand and fitted with evenly spaced, sharp barbs that create a strong physical and psychological deterrent.

🛠️ Key Features and Advantages High tensile steel barbed wire

✔ High Strength & Tension Retention

High tensile steel holds its tension over long distances, making it ideal for fencing where post spacing exceeds 4 meters. It resists stretching, impact, and thermal contraction better than low-carbon alternatives.

✔ Reduced Maintenance

Because the wire doesn’t sag or loosen easily, fences built with high tensile barbed wire require less frequent re-tensioning, saving on long-term labor and repair costs.

✔ Corrosion Resistance

Both the line wire and the barbing wire are heavily galvanized, providing excellent protection against rust and corrosion. This makes it suitable for wet, coastal, and high-humidity environments.

✔ Lightweight and Cost-Efficient

Despite its strength, high tensile wire is lighter than older low-carbon alternatives, allowing for easier transport, faster installation, and reduced need for closely spaced fence posts.

✔ Long Service Life

With proper installation and minimal maintenance, high tensile barbed wire fences can last 15–25 years depending on environmental exposure.

🧱 Typical Applications

▪ Agricultural Use

High tensile barbed wire is commonly used to confine cattle, sheep, and goats. Its durability ensures animals stay in and predators stay out.

▪ Perimeter Security

Warehouses, farms, factories, and remote installations use this fencing to establish clear, tamper-resistant boundaries.

▪ Military and Government Zones

Due to its resilience and deterrent capacity, it is a standard component in fencing for prisons, border zones, airports, and other sensitive areas.

▪ Construction Sites and Temporary Events

When installed on mobile posts, high tensile barbed wire offers quick and effective fencing for short-term security needs.

🧤 Handling and Installation Tips High tensile steel barbed wire

- Always uncoil using a spinning jenny – Never drop the coil or let it spring open; the tension can cause serious injury.

- Wear protective gear – Leather gloves, long sleeves, and eye protection are essential. Barbs can cause deep lacerations.

- Use a come-along and ratchet – This tool helps you apply even tension across long stretches. “Pull tight once, pull tighter tomorrow.”

- Secure every barb at the post – Use fencing staples or clips to fasten barbs directly to posts. This prevents creep and maintains tension.

- Space your posts properly – For high tensile wire, 4 to 6 meters between posts is standard. Bracing is critical at corners and ends.

- Monitor fence integrity regularly – Look for broken strands, loose clips, or rust spots, especially after storms or high animal pressure.

🧾 Choosing the Right Wire: A Summary

| Application Type | Recommended Wire Type | Reason |

|---|---|---|

| Low-cost, short-term fencing | Single-twist low carbon | Lightweight, cheap, easy to install |

| Standard agricultural fencing | Double-twist high tensile | Strong, long-lasting, low maintenance |

| Maximum security | Reverse or traditional double-twist | Highest tension and barb density |

When selecting barbed wire, consider the local regulations on fence height and placement, especially in urban or roadside areas. Also factor in the labor availability for installation and upkeep.

🧩 Final Thoughts High tensile steel barbed wire

High tensile steel barbed wire represents a long-term investment in security and containment. It’s not just a physical barrier — it’s a statement of deterrence and protection. When installed correctly, it can outperform and outlast cheaper alternatives by years, offering lower lifetime cost and greater peace of mind.

Whether you’re protecting crops, livestock, inventory, or borders, choosing the right specifications and installation method will ensure your barbed wire fence stands strong against time, pressure, and intent.