Perforated Metal – Durable, by BMP

- Material: Carbon, Galvanized, Stainless Steel, Aluminum

- Max Thickness: 8mm

- Max Width: 3000mm

- Sample: Available

- Common Size: 40”x120”, 36”x120” or 1220mm x 2440mm

- Brand Name: bmp

- Certification: ISO9001, ISO14001, ISO45001

- Minimum Order Quantity: 10-30 sqm

- Price: $15-$30

- Packaging Details: Wrapped with plastic film on wooden/steel pallets

- Delivery Time: 5-10 days if in stock

- Payment Terms: D/P, T/T, D/A

Category:Perforated Steel

Introduction

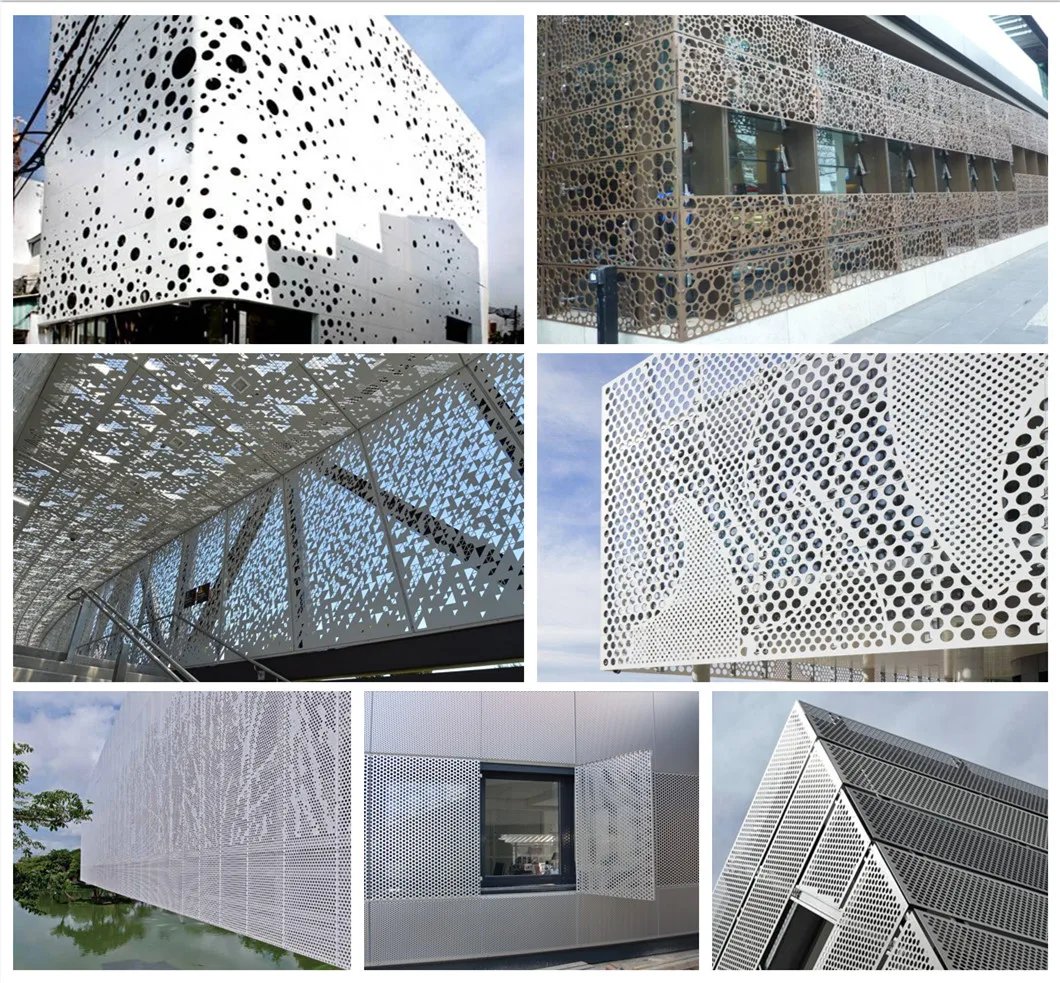

Perforated Metal: A Versatile Solution for Construction and Decoration

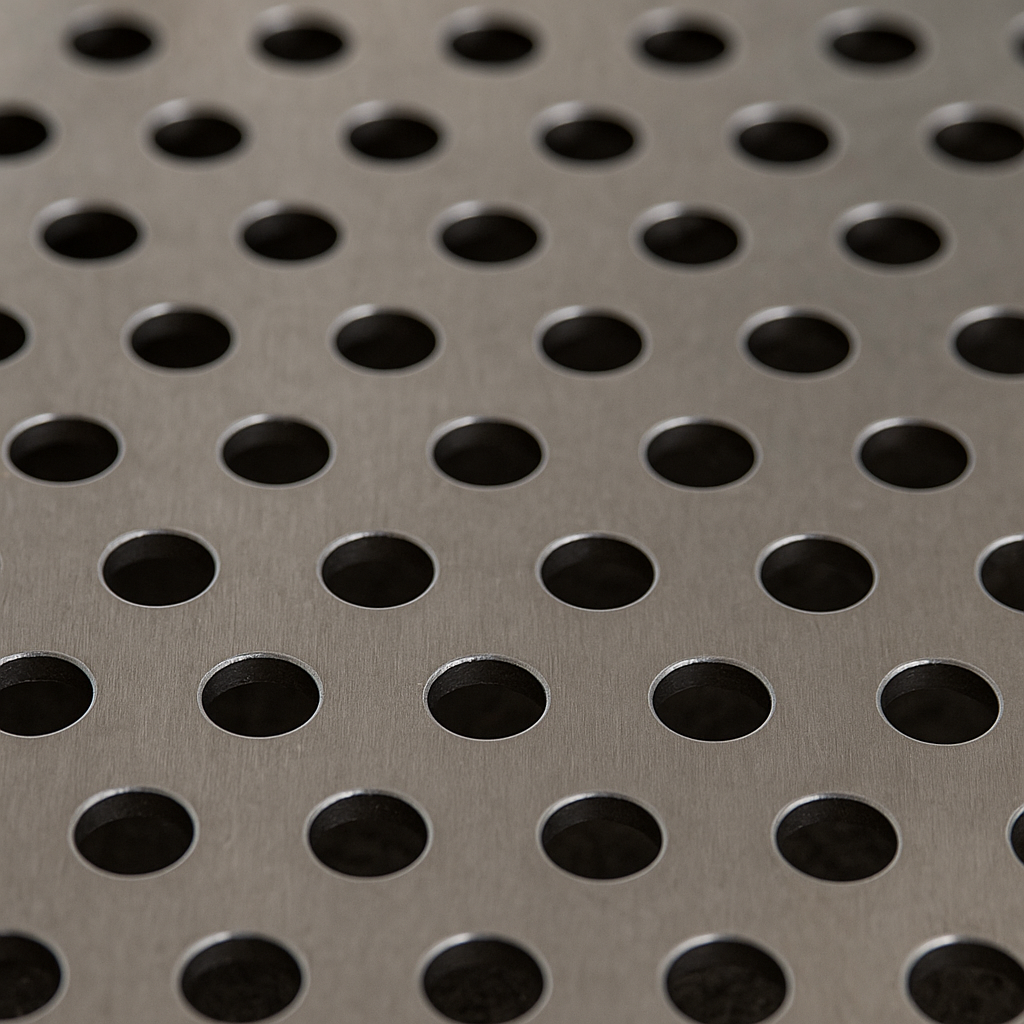

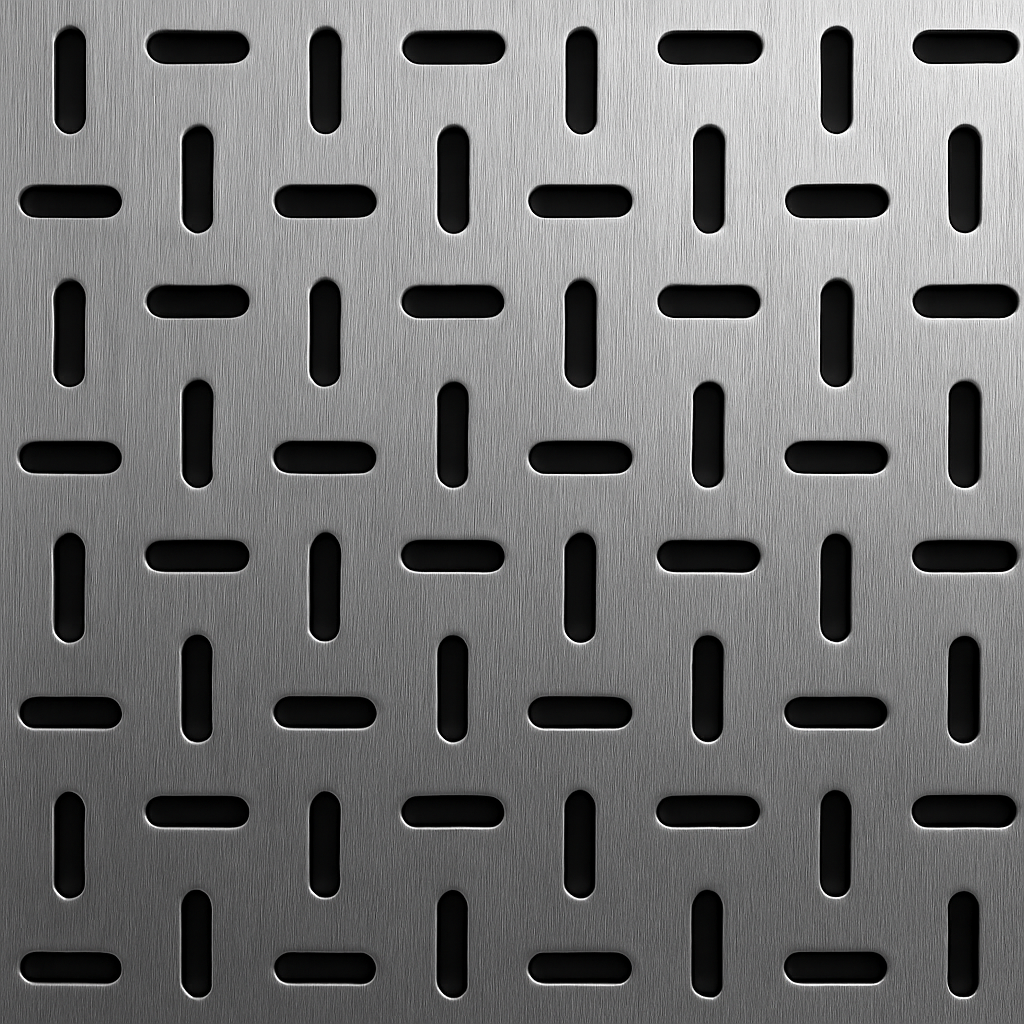

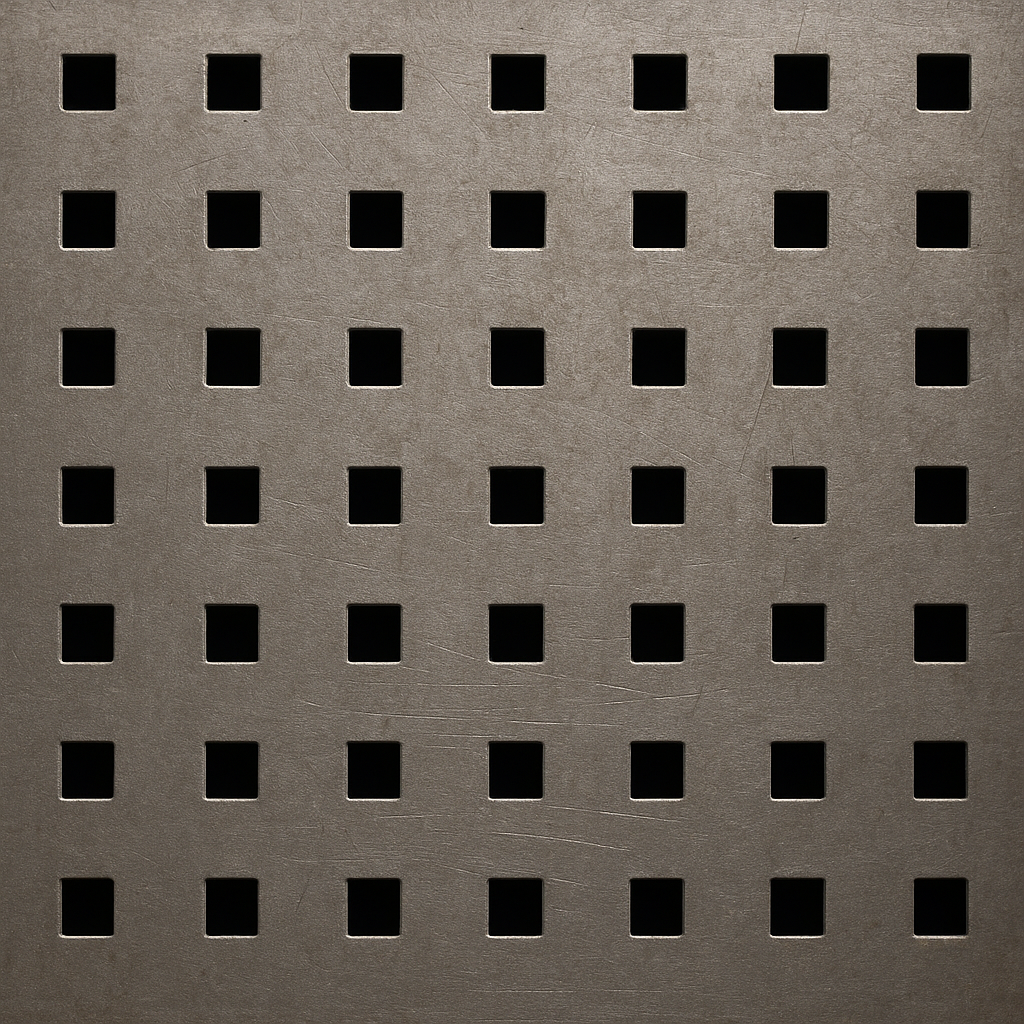

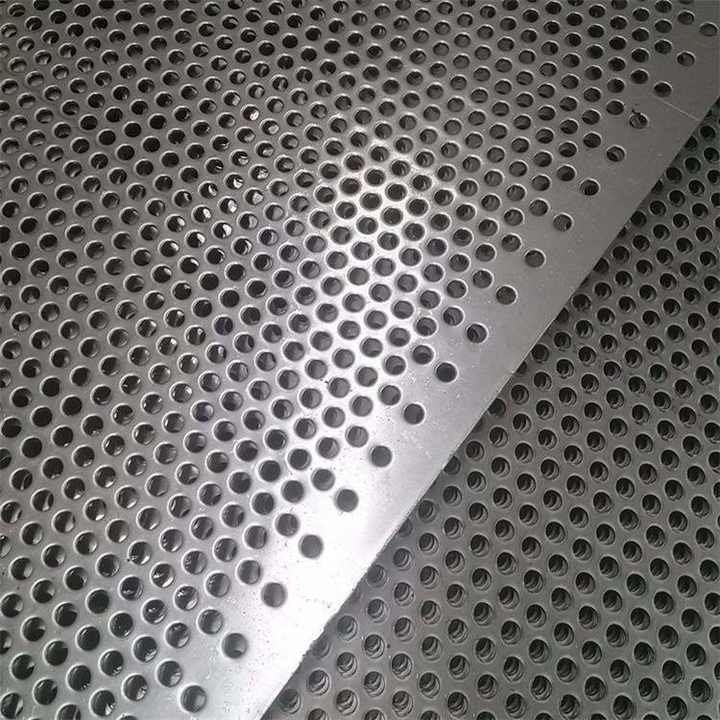

Perforated metal, also known as perforated mesh sheet, is a highly versatile construction material with a wide range of applications. It features various hole shapes like round, square, rectangle, diamond, and hexagonal, making it suitable for different industries and purposes. Available in a range of materials such as stainless steel, aluminum, and galvanized steel, perforated metal is customizable in thickness, hole size, and color.

Perforated metal sheets are versatile materials widely used in industrial, architectural, and decorative applications. Their functionality is defined by the hole patterns, which offer unique characteristics for various uses. This article explores the four main types of perforated metal: Round, Square, Slotted, and Decorative, including their applications, benefits, and technical specifications.

Quality Control Process

Material Inspection: Ensuring the Right Foundation

Ensuring the highest standards of quality in perforated metal products begins with the inspection of raw materials. High-quality materials such as stainless steel, aluminum, and galvanized steel are thoroughly examined before they enter the production line. Each sheet is inspected for imperfections, including surface rust, scratches, or thickness irregularities. This initial step ensures that only the best materials are used for production.

Pre-Production Testing: Verifying Durability and Resistance

Once Perforated Metal material passes inspection, it undergoes pre-production testing. A sample is selected for strength, durability, and corrosion resistance testing. This step ensures that the material can withstand the conditions it is meant to endure, particularly in challenging environments where performance is critical.

Precision Punching: Achieving Accuracy in Design

The next phase involves the punching process, where precision is key. Modern punching machines are used to create the desired hole patterns, which can range from round and square to custom shapes. These machines are regularly calibrated and checked to ensure that each hole is accurately placed with the correct size and spacing. The process is continuously monitored to prevent any variation that could impact the quality or functionality of the final product.

Surface Treatment: Enhancing Durability and Aesthetics

After the perforating process, the Perforated Metal undergoes surface treatments such as anodizing, galvanizing, or coating. These treatments enhance the material’s resistance to corrosion and environmental wear. During this stage, the uniformity of the coating is carefully checked to ensure a consistent finish. The sheets are visually inspected for smoothness, ensuring there are no inconsistencies or defects that could affect their durability or appearance.

Dimensional Accuracy: Ensuring Perfect Fit and Function

Dimensional accuracy is another critical aspect of quality control. Finished sheets are measured against the specified dimensions, including thickness, length, and width. Additionally, the size of the holes is checked to ensure that they align with the specified design. Tolerances are strictly adhered to, and any discrepancies beyond the acceptable range are corrected or discarded.

Strength and Durability Testing: Ensuring Long-Term Reliability

To guarantee the material’s strength and ability to withstand harsh conditions, random samples undergo rigorous strength and durability testing. These tests assess the material’s resistance to bending, impact, and wear, ensuring that the final product will perform reliably in real-world applications.

Aesthetic Inspection: Verifying Visual Quality

Once the material has passed all functional tests, it moves on to aesthetic inspections. The hole patterns are checked for uniformity, and any visual imperfections, such as discoloration or surface blemishes, are addressed. This ensures that the final product is not only functional but also visually appealing, particularly for decorative applications where appearance is just as important as performance.

Final Review and Packaging: Safeguarding for Shipment

Before the product is shipped to customers, it undergoes a final review by a quality control supervisor. This final inspection ensures that all the specifications are met and that the product is ready for delivery. Each perforated sheet is then carefully packed to prevent damage during transportation. Protective plastic wrapping and sturdy wooden or steel pallets are used to safeguard the product throughout the shipping process.

Customer Feedback: Continuous Improvement and Satisfaction

After the product reaches its destination, customer feedback is actively monitored. This feedback loop helps to identify any potential issues and provides valuable insights that can improve future production runs.

Specifications

| Parameter | Detail |

|---|---|

| Hole Shape | Round, Square, Rectangle, Diamond, Hexagonal |

| Thickness | 0.1mm – 12mm |

| Length | 2m, 2.4m, 3m (Custom lengths available) |

| Material | Stainless Steel, Aluminum, Galvanized Steel |

| Hole Size | 0.1mm – 100mm (Custom sizes available) |

| Surface Treatment | PVC Coating, Polishing, Anodizing, Galvanizing |

| Color | Silver, Black, White (Custom colors available) |

| Minimum Order Quantity | 1 piece |

| Applications | Construction Wire Mesh, Decorative Mesh, etc. |

Production Process of Perforated Metal

- Material Selection: The first step involves selecting the right material for perforated metal. Stainless steel, aluminum, and galvanized steel are commonly used, based on the required durability and application.

- Punching Holes: In the next step, the metal sheet is fed into a machine that precisely punches holes in the desired shapes and sizes. The machines can be customized for round, square, or custom hole shapes.

- Surface Treatment: After the perforation process, the sheets undergo surface treatments such as PVC coating, polishing, anodizing, or galvanizing to enhance corrosion resistance and aesthetic appeal.

- Customization: At this stage, additional customizations such as custom colors, hole sizes, and sheet dimensions are made according to client requirements.

- Packaging and Shipping: The final product is carefully packed to prevent any damage during transit. It is typically wrapped in plastic film and placed on wooden or steel pallets for secure delivery.

|

|

|

|

Applications of Perforated Metal

Perforated metal sheets are used in a variety of industries due to their strength, versatility, and aesthetic appeal. Here are some common applications:

- Architecture and Design: Perforated metal is widely used in facades, sunscreens, ceilings, and partitions. Its ability to provide both functionality and an attractive design makes it popular in architectural projects.

- Soundproofing: Thanks to its high open area, perforated metal allows for better airflow and is often used in soundproofing systems to control noise levels in various environments.

- Ventilation: It is also used for ventilation purposes, especially in industrial settings where airflow is critical. The holes allow air to pass through efficiently while maintaining structural integrity.

- Filtering and Screening: In industries such as mining, food processing, and pharmaceuticals, perforated metal is used as a filtration material to separate particles or components.

- Protective Mesh and Barriers: Perforated metal is used in manufacturing safety fences, guardrails, and other protective mesh products due to its durability.

Benefits of Perforated Metal

- Corrosion Resistance: When made from materials like stainless steel or aluminum, perforated metal is highly resistant to corrosion, making it suitable for both indoor and outdoor applications.

- Durability: The metal sheets are strong and durable, able to withstand harsh environments and physical impacts.

- Customization: It can be customized in terms of thickness, hole size, material, and color to meet specific requirements.

- Aesthetic Appeal: The perforated designs can enhance the visual appeal of buildings and other projects, providing a modern and sleek look.

- Improved Ventilation and Airflow: The perforated design allows for efficient airflow and ventilation, making it ideal for use in systems that require airflow management.

Packing and Shipping

Proper packaging is essential to ensure that perforated metal sheets arrive at their destination in excellent condition. The sheets are typically packaged with:

- Plastic Film: Wrapping the perforated metal sheets in plastic film helps to protect them from scratches and minor damage.

- Wooden/Steel Pallets: The sheets are placed on sturdy wooden or steel pallets to prevent any bending or damage during transit.

- Clear Labeling: Each package is labeled with product details, destination information, and any special handling instructions to ensure smooth delivery.

Shipping is handled through reputable carriers with tracking information and insurance, ensuring that the perforated metal sheets arrive safely and on time.

FAQ

- What is high open area perforated metal? High open area perforated metal has a larger percentage of open spaces compared to standard perforated sheets, making it ideal for applications that require increased airflow, filtration, or ventilation.

- What materials can perforated metal be made from? Perforated metal can be made from stainless steel, aluminum, galvanized steel, or other custom materials based on the specific requirements of the project.

- How are perforated metal sheets used in soundproofing? The high open area of the perforated holes allows sound waves to pass through while providing a material that helps absorb sound, making it ideal for soundproofing applications.

- Can I customize the hole shapes and sizes? Yes, perforated metal sheets can be customized with various hole shapes (round, square, etc.) and sizes, and custom designs can be accommodated.

- Where can perforated metal be used? Perforated metal is used in various industries, including architecture, construction, filtration, ventilation, and soundproofing. It is also used in industries such as mining, food processing, and pharmaceuticals.

|

|

|

|

Conclusion

Perforated metal is a highly versatile material with numerous applications in construction, decoration, filtration, and soundproofing. Its strength, durability, and aesthetic flexibility make it an ideal choice for a wide range of projects. With customizable sizes, hole shapes, and materials, perforated metal offers solutions for industries as diverse as architecture, mining, and food processing. Whether you’re in need of decorative panels, protective mesh, or filtration components, products can be tailored to meet your needs.

BMP perforated metal is produced to the highest standards, with options for customization, quick delivery, and a reliable supply. For more information or to place an order, contact us today!