Tecco Mesh: The Ultimate Solution BMP

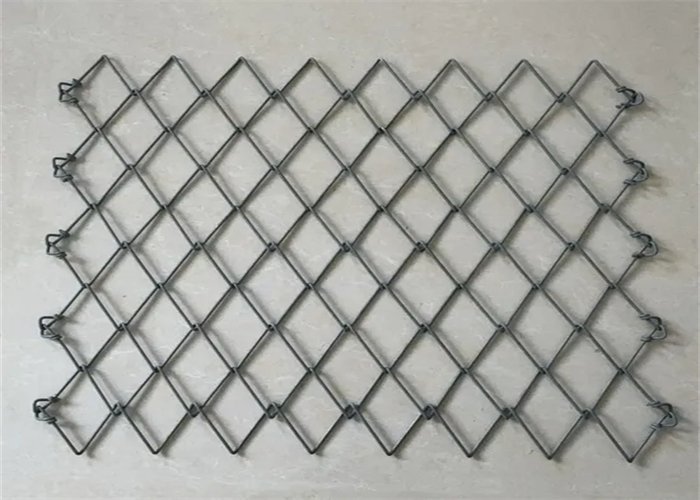

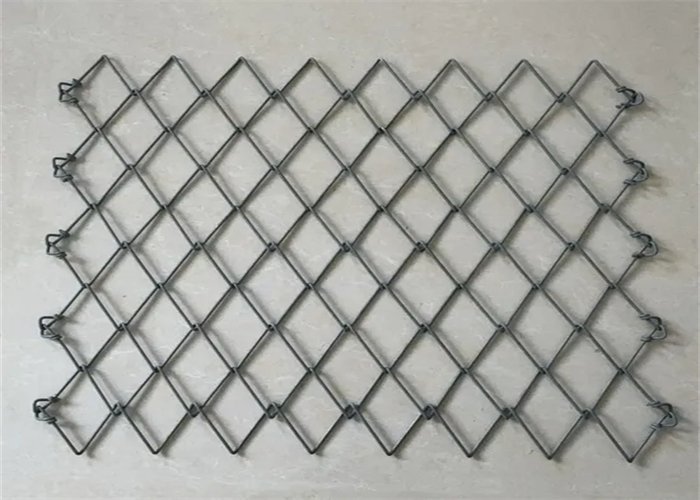

- Hole Shape: Diamond

- Wire Diameter: 3 mm or 4 mm

- Mesh Size: Inscribed circle diameter is 65 mm

- Tensile Strength: Minimum 1770 MPa

- Corrosion Treatment: Hot-dipped galvanized or Zinc-Aluminum coated

- Zinc Thickness: No less than 150 g/m²

- Breaking Load of Single Wire: 12.5 kN

- Roll Width: 1 m – 3.5 m

- Roll Length: 10 m – 30 m

- Components: Steel wire mesh, nail, spike plate, clips

- Company Type: Factory direct sell

- Weight: 1.8 kg/m²; 3.3 kg/m²; 2.6 kg/m²

- Specification: Wire diameter 3.0 mm

- Trademark: BMP

- Origin:China

- HS Code: 73144100

Category:RockFall Netting

Introduction

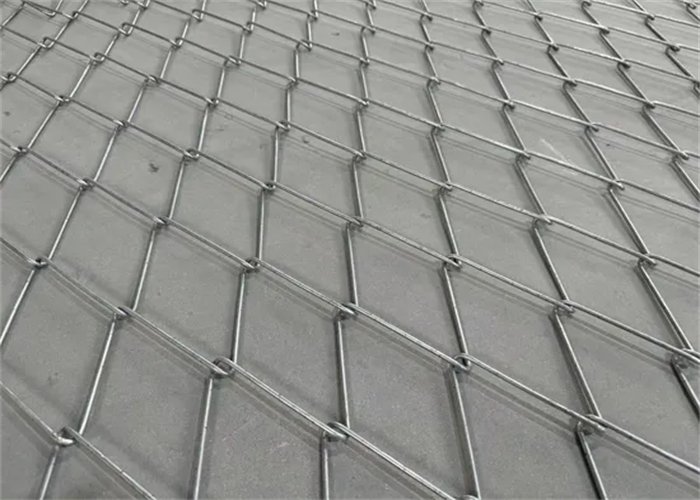

Rockfall Tecco Mesh is a high-tensile wire mesh designed for slope stabilization and rockfall protection. It is made from high-quality steel wire with a unique double twist mesh type, providing exceptional strength and flexibility. The mesh is engineered to absorb and distribute impact forces, effectively preventing rockfall, debris flow, and other natural hazards. This makes it an ideal choice for use in road construction, mining, and various industries requiring geohazard protection. The mesh is available in customizable sizes, offering a perfect fit for any slope stabilization system.

Details

Tecco mesh. |

Steel anchor. |

Claw type spike plate. |

Sewing rope. |

Specifications

Technical Data |

TECCO® G45/2 |

TECCO® G65/3 |

TECCO® G65/4 |

|---|---|---|---|

| Wire Diameter | 2 mm | 3 mm | 4 mm |

| Tensile Strength of Steel Wire | ≥ 1770 N/mm² | ≥ 1770 N/mm² | ≥ 1770 N/mm² |

| Tensile Strength of Steel Wire Mesh | ≥ 85 kN/m | ≥ 150 kN/m | ≥ 250 kN/m |

| Diagonal | 62 x 95 mm | 83 x 143 mm | 83 x 138 mm |

| Mesh Width | 48 mm | 65 mm | 63 mm |

| Number of Meshes Transversal | 16.1 pcs/m | 12 pcs/m | 12 pcs/m |

| Number of Meshes Longitudinal | 10.5 pcs/m | 7 pcs/m | 7.2 pcs/m |

| Weight per m² | 1.15 kg/m² | 1.65 kg/m² | 3.3 kg/m² |

| Corrosion Protection | GEOBRUGG SUPERCOATING® | GEOBRUGG SUPERCOATING® | GEOBRUGG SUPERCOATING® |

| Compound of Corrosion Protection | 95% Zn / 5% Al | 95% Zn / 5% Al | 95% Zn / 5% Al |

Applications:

Rockfall Tecco Mesh is perfect for use in situations where slope stability is a concern. Its primary application is for rockfall protection, making it highly suitable for:

- Road construction projects

- Mining areas

- Construction of tunnels and bridges

- Hillsides and steep slopes

- Infrastructure protection in geohazard zones

By installing Rockfall Tecco Mesh, engineers can effectively stabilize slopes and prevent dangerous rockfalls that may damage infrastructure or put lives at risk.

Benefits:

- High Tensile Strength: With a wire diameter of 3.0 mm and tensile strength of 1770 N/mm², the mesh can withstand heavy impacts and provide long-lasting protection.

- Lightweight: Weighing just 2.5 kg/m², the mesh is easy to handle and install, reducing labor costs and installation time.

- Customization: Available in different roll widths (2 m ~ 3.5 m) and lengths (30 m or customized), the mesh can be tailored to fit specific project requirements.

- Durability: The heavy galvanization ensures that the mesh is resistant to corrosion, providing long-term protection even in harsh weather conditions.

- Flexible Design: The unique double twist design allows the mesh to adapt to the natural contours of the slope, ensuring a seamless installation that follows the landscape’s shape.

Production Process:

The production of Rockfall Tecco Mesh involves the following steps:

- Material Selection: High-tensile steel wire is selected based on its strength, durability, and corrosion resistance.

- Wire Coating: The wire is coated with a heavy galvanized layer or a Galfan wire coating (95% Zn / 5% Al) to prevent rust and corrosion.

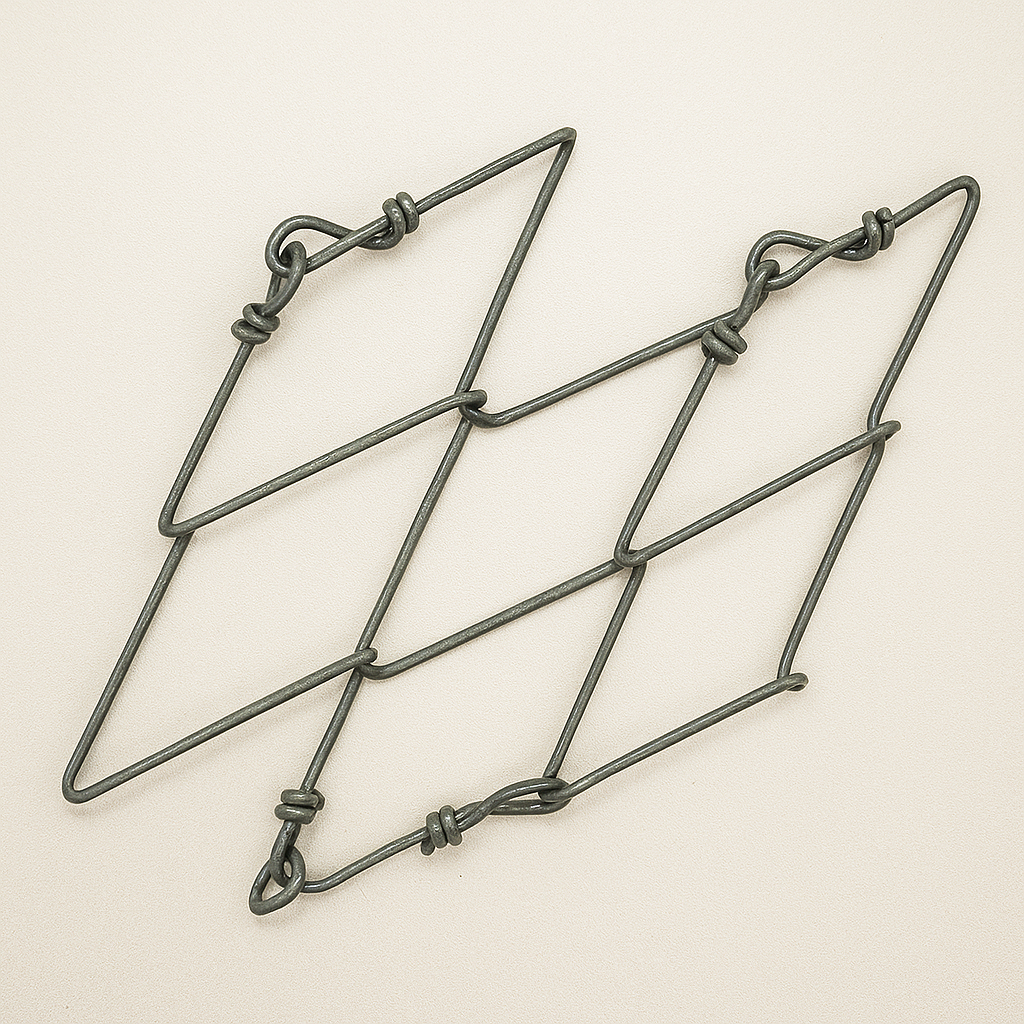

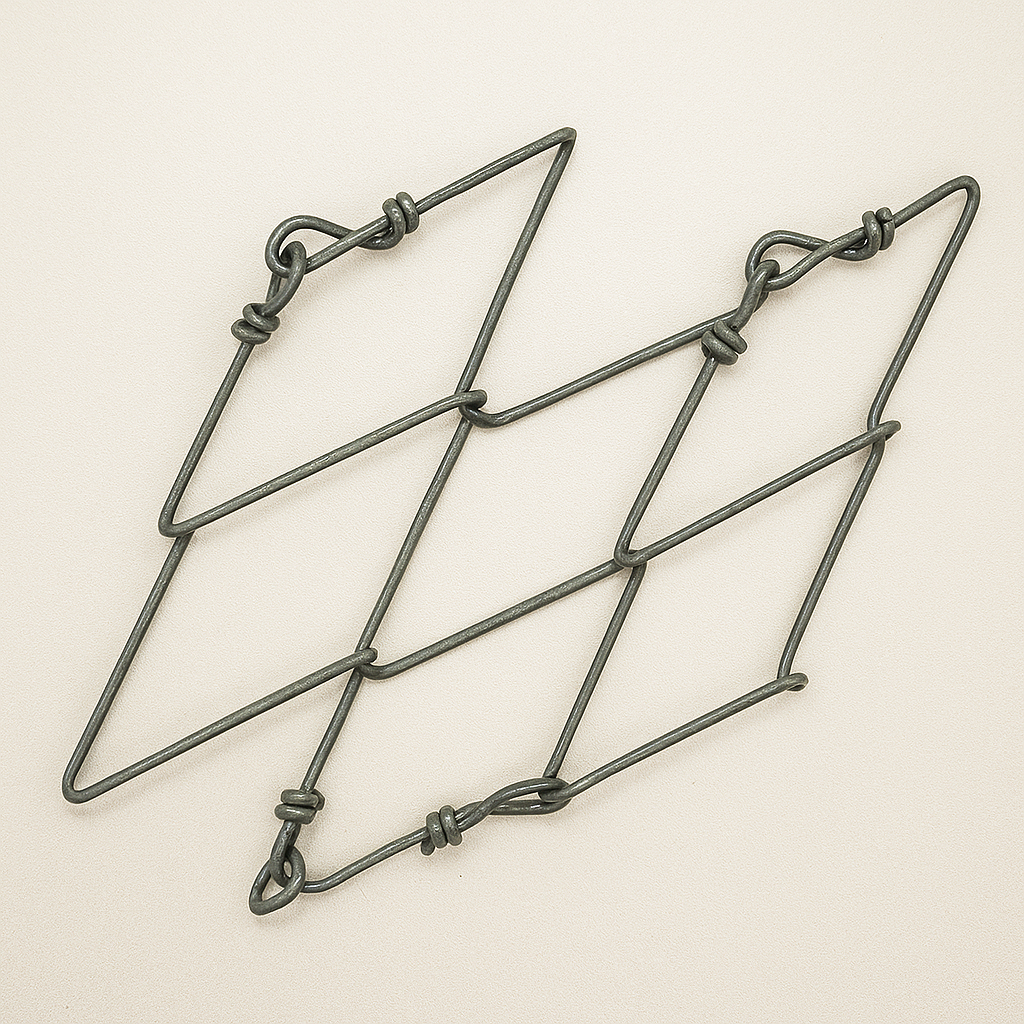

- Mesh Manufacturing: The steel wires are woven into a double twist pattern, which increases the mesh’s tensile strength and impact resistance.

- Knitting: The mesh is tightly knotted at the edges to enhance its strength and prevent any unravelling during installation.

- Cutting: The mesh is then cut into the desired roll widths and lengths, customized to meet the specifications of each project.

- Quality Control: Each roll undergoes strict quality inspection to ensure it meets the required tensile strength of ≥1,770 N/mm² and mesh strength of 150 kN/m.

Packing and Delivery:

The Rockfall Tecco Mesh is packaged and delivered efficiently to ensure quick installation and site readiness:

- Packaging: The mesh is rolled up and packaged on sturdy pallets to prevent any damage during transport.

- Delivery Time: Delivery takes 10-20 days after payment, ensuring quick turnaround for projects.

- Customization: Mesh rolls are available in standard 30 m lengths or can be customized to meet specific project requirements.

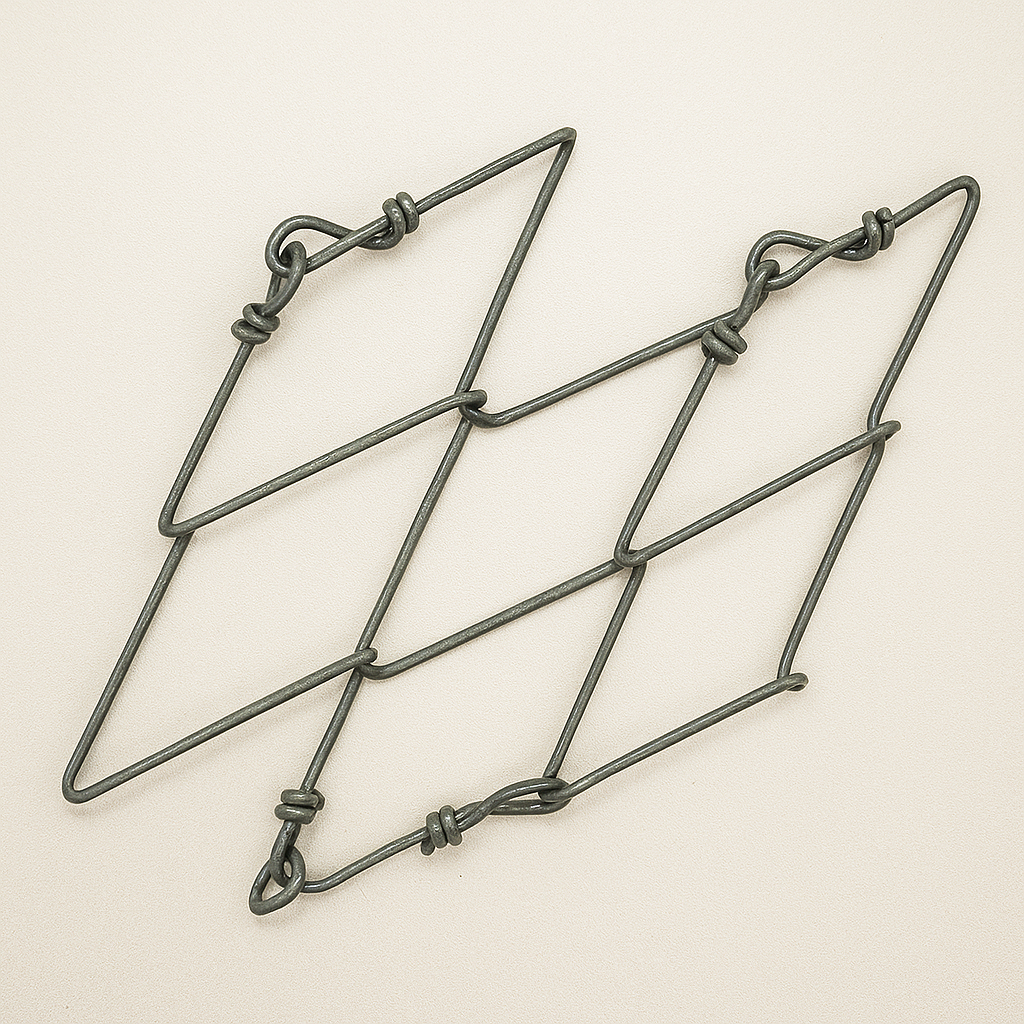

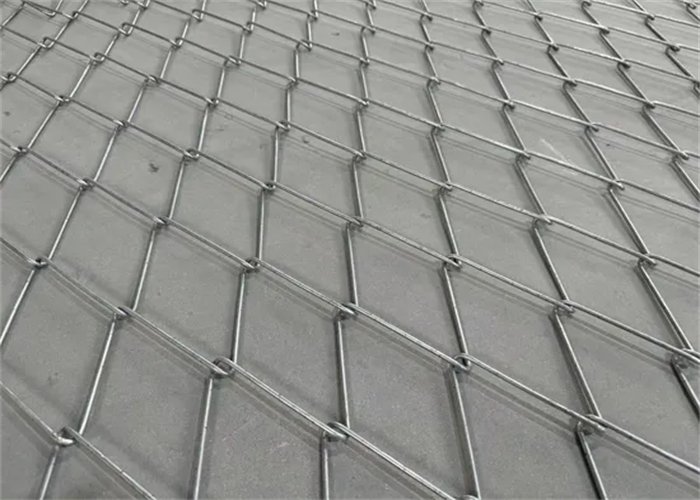

| Rhomboid mesh is stable in the irregular mountains. | Knotted ends make the tecco mesh stable and solid. |

|

|

Conclusion:

The Rockfall Tecco Mesh system offers an excellent solution for slope stabilization and geohazard protection. Its high-tensile strength, corrosion-resistant coating, and customizable size make it an essential tool for any construction or mining project requiring rockfall protection. Whether you’re working on steep slopes, in tunnels, or near other hazardous areas, Tecco Mesh provides superior protection against rockfalls and debris flows, ensuring safety and stability for the environment and people.

If you are in Qatar, for example, cities like Doha and Al Rayyan can benefit from the application of this advanced slope protection system, providing both safety and environmental stability.