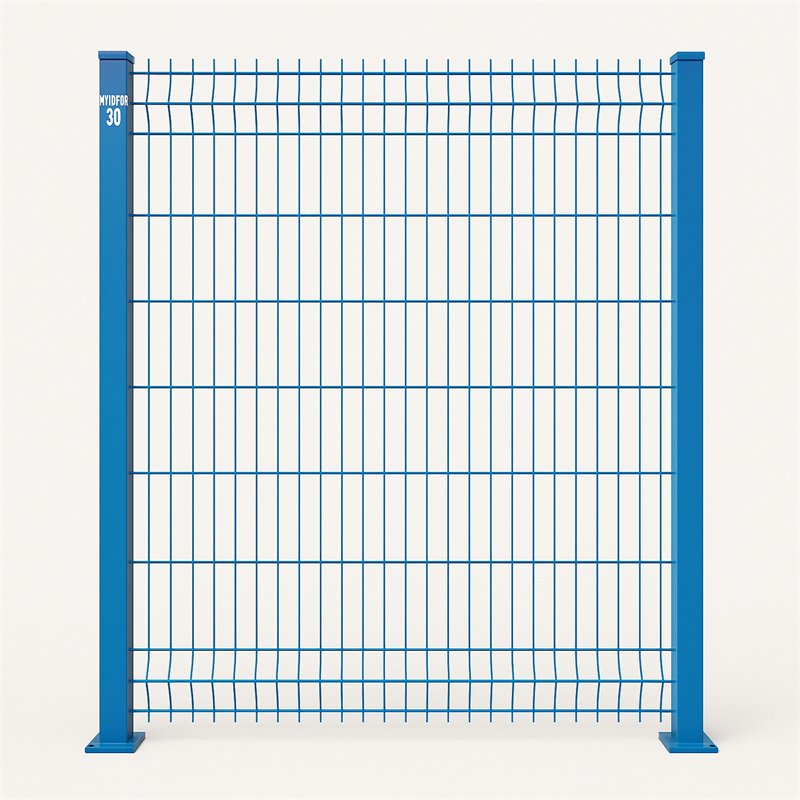

Welded Wire Mesh Panels

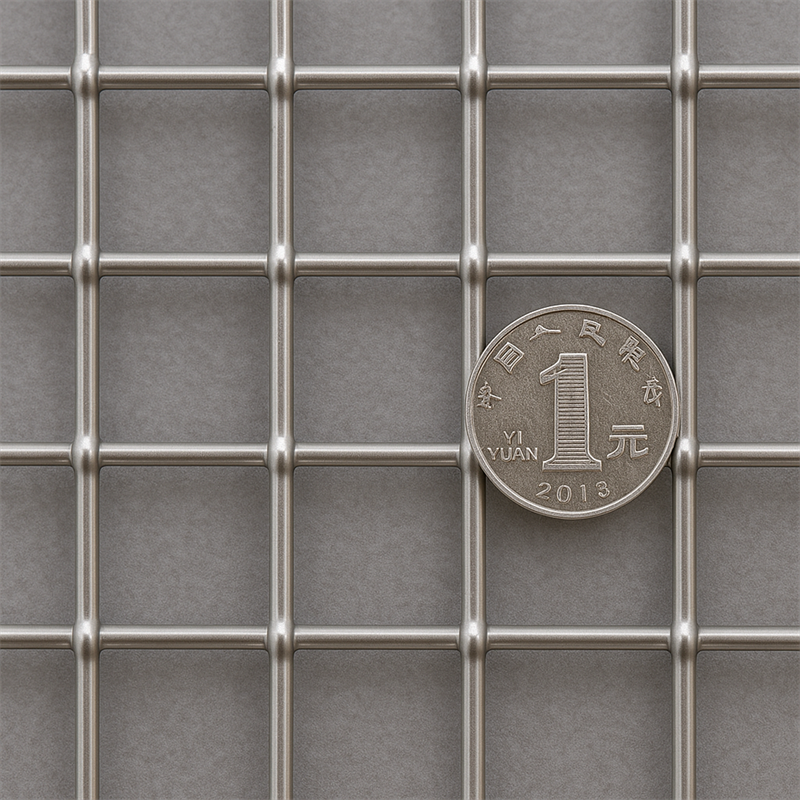

- Color: Silver

- Type: Welded Mesh

- Certification: ISO9001, SGS, TUV

- Condition: New

- Mesh Opening Size: 15 × 15 cm

- Sheet Size: 2.15 m × 6 m

- Wire Thickness: 3.7 mm

- OEM/ODM Services: Accepted

- Transport Package: With pallet / with bundles

- Specification: 15 × 15 cm, 2.15 m × 6 m

- Trademark: BMP

- Country of Origin: China

- HS Code: 7314310000

- Production Capacity: 500,000 rolls per month

- Price Range: $22.31 – $49.99 per piece

Category:Product, Welded Wire Mesh

Introduction

Welded wire mesh panels are a type of screen made from low carbon steel wire or stainless steel wire that is electrically welded at each intersection. They are widely used in industrial, commercial, and residential applications due to their strength, versatility, and ease of installation.

This guide covers their materials, manufacturing process, specifications, applications, and benefits.

1. Materials Used

Welded mesh panels are typically made from the following materials:

- Low Carbon Steel Wire: Cost-effective, suitable for most general purposes.

- Stainless Steel Wire (304, 316): Corrosion-resistant, ideal for food-grade, marine, or harsh environments.

- Aluminum-Magnesium Alloy Wire: Lightweight with strong anti-corrosion performance.

- Galvanized Wire: For improved corrosion resistance (either pre-galvanized or post-weld galvanized).

2. Manufacturing Process

- Wire Straightening: Raw wire is straightened before welding.

- Welding: Wires are arranged in a grid and welded at intersections using electrical resistance welding.

- Surface Treatment:

-

Electro-Galvanizing: Light zinc coating, good for indoor use.

-

Hot-Dip Galvanizing: Heavy-duty coating, suitable for outdoor and corrosive environments.

-

PVC Coating: Adds a plastic layer for color, UV protection, and better aesthetics.

-

- Cutting and Shaping: Panels are cut to size and optionally framed or bent.

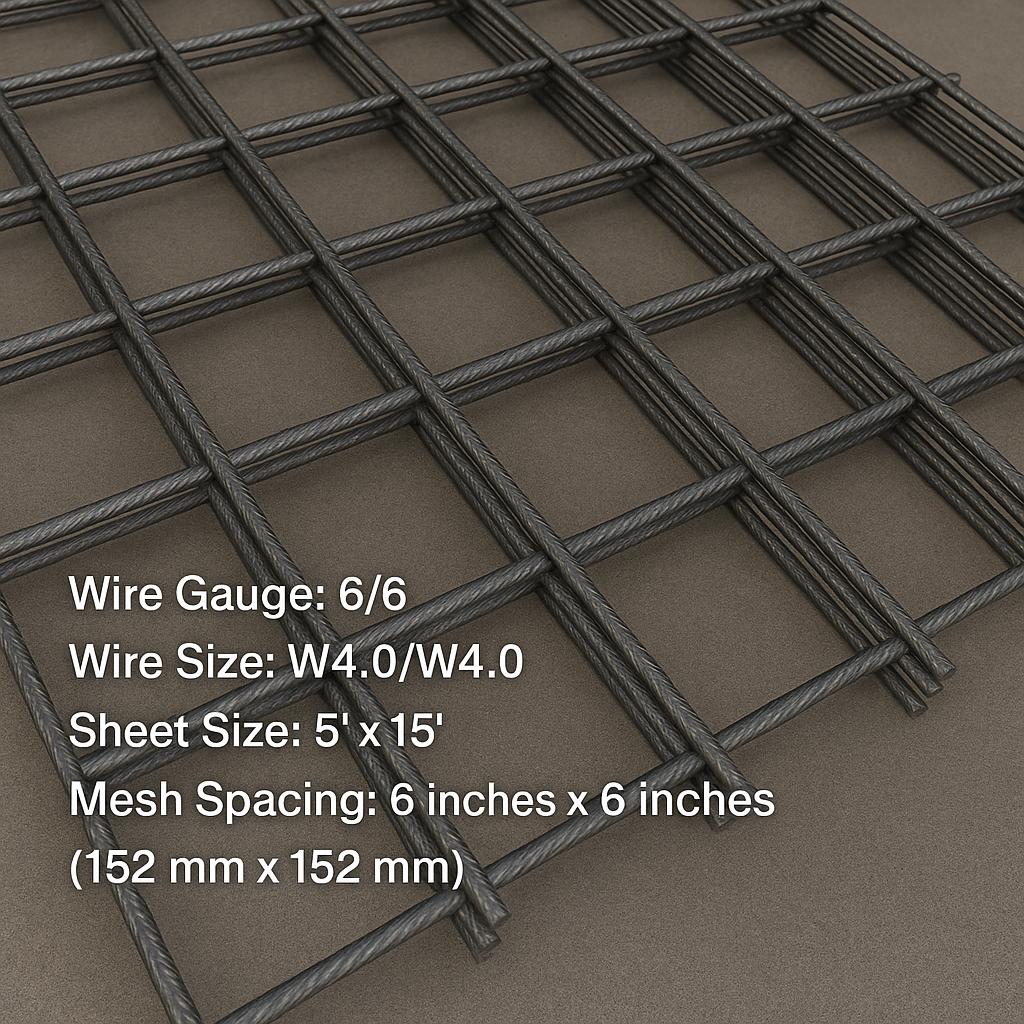

3. Specifications Welded Wire Mesh Panels

| Item | Specification Description |

|---|---|

| Material | Low carbon steel wire, stainless steel wire, aluminum-magnesium alloy wire |

| Wire Diameter | 0.56–2.77 mm (corresponding to 24–12 gauge) |

| Mesh Opening Size | 6.4 mm × 6.4 mm to 50.8 mm × 50.8 mm (1/4″ to 2″) |

| Surface Treatment | Electro-galvanized, hot-dip galvanized, PVC coated |

| Coating Thickness | 0.5 mm – 1 mm |

| Common Colors | White, green, black (customizable) |

| Tensile Strength | 300–450 N/mm² |

| Elongation Rate | Minimum 15% |

| Common Panel Size | 1800 mm × 3000 mm (custom sizes available) |

| Roll Size | Width: 0.5–1.8 m; Length: 5–30 m (customizable) |

| Applications | Animal cages, plant supports, plaster mesh, floor heating systems, reinforcement, etc. |

Mesh Size and Wire Diameter Combinations (Before and After PVC Coating)

| Mesh Size (mm) | Wire Gauge (BWG) | Wire Diameter Before Coating (mm) | After Coating (mm) |

|---|---|---|---|

| 6.4 × 6.4 | 24–22 | 0.56–0.71 | 0.90–1.05 |

| 9.5 × 9.5 | 23–19 | 0.64–1.07 | 1.00–1.52 |

| 12.7 × 12.7 | 22–16 | 0.71–1.65 | 1.10–2.20 |

| 19.1 × 19.1 | 21–16 | 0.81–1.65 | 1.24–2.40 |

| 25.4 × 25.4 | 21–14 | 0.81–2.11 | 1.28–2.90 |

| 50.8 × 50.8 | 16–12 | 1.65–2.77 | 2.20–3.61 |

Common Welded Mesh Roll Sizes

| Mesh Opening (Inch) | Width × Length (Feet) |

|---|---|

| 1/2″ | 3′ × 50′ |

| 1/2″ | 4′ × 50′ |

| 3/4″ | 5′ × 50′ |

| 1″ | 6′ × 50′ |

Common Welded Mesh Panel Sizes

| Mesh Size (mm) | Wire Diameter (mm) | Panel Size (mm) |

|---|---|---|

| 50 × 50 | 3.5 | 2440 × 1220 |

| 100 × 100 | 4.0 | 2000 × 3000 |

| 150 × 150 | 4.5 | 2200 × 3500 |

| 200 × 200 | 5.0 | 2200 × 3500 |

4. Types of Welded Wire Mesh Panels

- Galvanized Welded Mesh Panel: Used in construction, fencing, and cages.

- Stainless Steel Welded Mesh Panel: Ideal for high-hygiene or corrosive areas.

- PVC Coated Mesh Panel: Common in residential fences and garden projects.

- Heavy-Duty Mesh Panel: Used for industrial partitions, barriers, or reinforcing concrete.

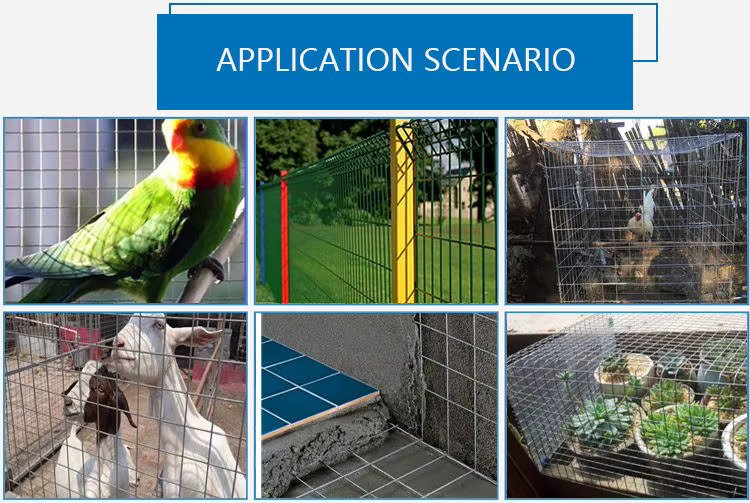

5. Applications

Welded mesh panels serve a wide range of applications:

Construction Industry

- Concrete reinforcement

- Wall rendering support (plaster mesh)

- Road pavement layers

Agriculture & Horticulture Welded Wire Mesh Panels

- Animal cages

- Livestock fencing

- Plant support grids

Security & Infrastructure

- Boundary fencing

- Security cages

- Window and machinery guards

Residential & Decorative

- Garden fencing

- Partition panels

- Custom wall features

6. Advantages Welded Wire Mesh Panels

- Strength & Stability: Rigid structure, especially compared to chain link or woven mesh.

- Ease of Installation: Panels are prefabricated and ready to mount or weld.

- Corrosion Resistance: Available in multiple finishes to suit environmental needs.

- Customizable: Available in various sizes, mesh openings, and coatings.

- Low Maintenance: Durable materials reduce the need for frequent replacement.

7. Considerations When Choosing

- Environment: Indoor vs. outdoor, corrosive exposure, aesthetic needs.

- Mesh Size & Wire Gauge: Depends on the strength and visibility required.

- Surface Treatment: Choose based on longevity and budget.

- Panel or Roll: Rolls for continuous applications; panels for rigid structural use.

Conclusion Welded Wire Mesh Panels

Welded wire mesh panels are a practical solution for a variety of industries due to their durability, adaptability, and cost-effectiveness. Whether you need structural reinforcement, security fencing, or decorative elements, welded mesh panels provide an efficient and long-lasting choice.

For best results, always select specifications that match your application requirements, and consider surface treatments for long-term durability.