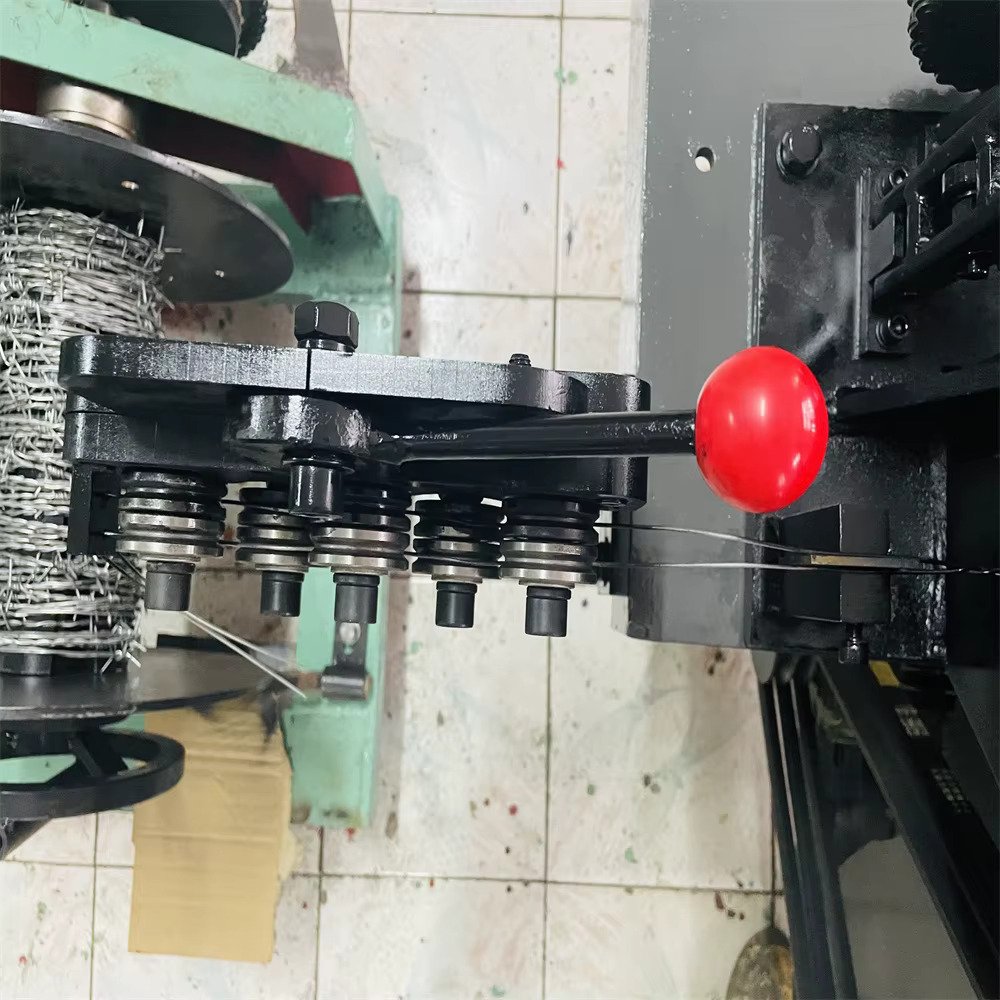

barbed wire machines

- Style: Horizontal

- Warranty: 1 Year

- Line Wire Diameter: 2.0–3.2 mm

- Barbed Wire Diameter: 1.8–2.4 mm

- Motor Power: 2.2 kW

- Barbed Distance Options:3″ (7.5 cm) 4″ (10 cm) 5″ (12.5 cm) 6″ (15 cm – likely based on context)

- Producing Speed: 3″: 540 m/h 4″: 720 m/h5″: 900 m/h6″: 1080 m/h

- Production Efficiency: 60 kg/h (Based on Line Wire 2.8 mm, Barbed Wire unspecified)

- Machine Dimension: 2700 × 1100 × 1300 mm

- Pay-off Rack: 3 pieces included

- Transport Package: According to customer’s request

- Specification Certification: ISO / SGS certified

- Trademark: BMP

- Origin: China

- HS Code: 84633000

- Production Capacity: 10 sets per month

Category:Barbed Wire, Product

Introduction

We offer high-performance barbed wire machines designed to meet various production needs with factory-direct pricing. Our barbed wire machine series includes three types: CS-A (Double Twisted), CS-B (Single Twisted), and CS-C (Reverse Twisted).

Advantages and Applications of the Barbed Wire Machine

The barbed wire machine is an essential piece of equipment for industries and sectors that require durable, high-performance fencing solutions. Whether for security, agriculture, or infrastructure, the machine provides an efficient and cost-effective way to manufacture different types of barbed wire. Below are the key advantages and applications of using a barbed wire machine.

|

|

|

|

Advantages of the Barbed Wire Machine

High Efficiency

Barbed wire machines are engineered for high-speed production. With automated operation and optimized winding and twisting speeds, these machines significantly increase output while minimizing manual labor. Available in multiple models—CS-A, CS-B, and CS-C—they offer flexibility to meet various production needs.

Low Energy Consumption

Built with energy efficiency in mind, the machines help reduce overall operational costs. Each model is designed to deliver maximum output with minimal power usage, making them ideal for both large factories and small-scale workshops.

Stable and Reliable Performance

The machine’s mechanical systems are precisely coordinated. Wire feeding, twisting, and rolling work in perfect sync, ensuring consistent product quality. All machines are made from high-quality components, resulting in a long service life and low maintenance requirements.

Easy Operation and Safety

Ease of use is a major benefit of the barbed wire machine. Operators benefit from a user-friendly interface equipped with an electronic counting system for accurate tracking. Additionally, the machine runs with low noise and minimal vibration, providing a safer and more comfortable working environment.

Versatile Production Options

These machines are highly versatile, capable of producing single twisted, double twisted, and reverse twisted barbed wire. They are compatible with standard galvanized steel wire and low-carbon steel wire, allowing for adaptability in different fencing applications.

|

|

|

|

Compact Structure

The barbed wire machine features a compact and efficient design, ideal for workshops with limited space. Despite its size, it delivers powerful performance and is easy to install and reposition when necessary.

Cost-Effective Solution

Combining competitive factory pricing with high production efficiency, the barbed wire machine offers excellent return on investment. Its low maintenance needs and durable construction reduce long-term costs, making it a smart choice for manufacturers.

Applications of the barbed wire machines

Security Fencing

Barbed wire machines are widely used to produce fencing for high-security areas, including military bases, prisons, and border zones. The strong, durable wire helps deter unauthorized access and enhances perimeter protection.

Agricultural Fencing

In the farming sector, barbed wire is essential for enclosing fields and pastures. It is commonly used to protect crops and livestock, ensuring animals stay within designated areas while keeping intruders out.

Industrial and Commercial Use

Factories, warehouses, and construction sites rely on barbed wire fencing for perimeter control. The wire adds an extra layer of protection against theft, vandalism, and unauthorized entry.

Highway and Railway Protection

Barbed wire is frequently installed along highways and railways to prevent public access to dangerous areas, improve safety, and reduce the risk of accidents or disruptions.

Residential Protection

In urban settings, barbed wire is often used on top of walls, fences, and gates to deter intruders. It serves as a simple yet effective security measure for homes and private properties.

Forestry and Wildlife Areas

The machine also supports applications in conservation areas. Barbed wire fencing helps manage animal movement and reduce human-wildlife conflict by creating secure boundaries around forests and reserves.

Barbed Wire Machine Models & Technical Specifications

| Item | CS-A | CS-B | CS-C |

|---|---|---|---|

| Motor | 3KW | 3KW | 2.2KW |

| Main Drive Shaft Speed | 402 turn/min | 402 turn/min | 357 r/min |

| Winding Speed | 470 turn/min | 470 turn/min | 125 turn/min |

| Pulling Speed | 134 turn/min | 134 turn/min | 134 turn/min |

| Rolling Speed | 30–255 turn/min | 30–255 turn/min | Friction Rolling |

| Main Machine Size | 1900 × 1300 × 980 mm | 1900 × 1300 × 980 mm | 1900 × 1300 × 980 mm |

| Rolling Machine Size | 1800 × 750 × 750 mm | 1300 × 500 × 500 mm | 1300 × 800 × 700 mm |

CS-A Double Twisted Barbed Wire Machines

The CS-A barbed wire machine is engineered for producing normal double twisted barbed wire. It consists of two coordinated parts—wire feeding and wire twisting—and includes four wire feeding reels. With reliable, flexible operation and stable performance, this machine is ideal for producing various multi-strand barbed wire mesh products. It ensures smooth operation for long production cycles.

CS-B Single Twisted Barbed Wire Machines

This model is a precision-built barbed wire machine composed of winding and rolling units, with three wire reels. Designed for high efficiency, it operates with low noise and energy consumption. The CS-B model features smooth movement, enhanced safety, and advanced electronic counting control for precise production metrics. Ideal for cost-effective single strand barbed wire production.

CS-C Reverse Twisted Barbed Wire Machine

The CS-C reverse twisted barbed wire machine is used to manufacture double-strand reverse twisted barbed wire. The machine complies with the GB/T343-94 standard for general-purpose low carbon steel wire. It’s widely used for defense, railways, highways, agricultural protection, and livestock fencing. The machine comprises reverse twisting, puncture winding, and friction rope winding units, supported by four winding reels. It features stable operation, low noise, low energy usage, and integrates advanced electronic counting for efficient control.

What types of barbed wire machines are available?

We offer three main models of barbed wire machines to suit different production requirements:

- CS-A Double Twisted Barbed Wire Machine: Suitable for producing standard double twisted barbed wire.

- CS-B Single Twisted Barbed Wire Machine: Designed for single strand twisting with high efficiency and low energy use.

- CS-C Reverse Twisted Barbed Wire Machine: Specialized for producing reverse twisted barbed wire, commonly used in security and fencing applications.

Each model comes with specific features, motor capacity, and winding mechanisms to handle various production volumes and wire specifications.

|

|

|

|

FAQ

What raw materials are suitable for barbed wire machines?

The barbed wire machine is compatible with low-carbon steel wire and galvanized wire. For CS-C (reverse twisted), the raw material must meet the GB/T343-94 standard for general-purpose low carbon steel wire. The diameter and strength of the wire used should match the machine’s design parameters for optimal performance.

How do I choose the right barbed wire machine model?

The selection depends on:

- Wire type and twist method (single, double, or reverse twisted)

- Production capacity requirements

- Energy usage preferences

- End-use of the barbed wire (agricultural, security, fencing, etc.)

|

|

|

|

If you’re producing standard fencing wire for farms, the CS-A or CS-B is often sufficient. For high-security or special applications like border fences or defense use, the CS-C is more appropriate.

What is the production capacity of the barbed wire machine?

Production capacity varies by model and operating speed. On average:

- CS-A and CS-B can produce barbed wire at speeds of 470 turns/min with a main drive shaft speed of 402 turns/min.

- CS-C operates slightly slower due to its more complex reverse twisting mechanism but still maintains a steady output suitable for industrial use.

Actual output also depends on operator efficiency, material quality, and machine maintenance.

How much space is required to install a barbed wire machine?

The main machine size is approximately 1900 × 1300 × 980 mm for all models. Rolling machine dimensions vary:

- CS-A: 1800 × 750 × 750 mm

- CS-B: 1300 × 500 × 500 mm

- CS-C: 1300 × 800 × 700 mm

You should allocate at least 10–15 square meters of workspace per machine to allow room for raw material storage, wire feeding, and operator movement.

Is the machine easy to operate?

Yes. All our barbed wire machines are user-friendly, even for first-time operators. They feature:

- Electronic counting systems for production tracking

- Stable mechanical structure

- Low noise and minimal vibration

- Simple control panels

Training can typically be completed in 1–2 days, and operational manuals are provided with each machine.

|

|

|

|

What are the maintenance requirements?

Routine maintenance ensures smooth, long-term operation. Key maintenance tasks include:

- Lubricating moving parts every 3–5 working days

- Checking wire feed tension to avoid jams or misalignment

- Inspecting the motor and electrical systems monthly

- Cleaning dust and debris from the machine surface and moving parts

Spare parts and technical support are usually available from the manufacturer or supplier.

Can the machine be customized?

Yes, customization is available for:

- Wire diameter range

- Barb spacing and length

- Reel design and wire feeding system

- Voltage and motor configuration (depending on your region)

Let us know your specific production needs, and we’ll provide tailored solutions.

What is the typical lifespan of a barbed wire machine?

With proper use and regular maintenance, the machine can last 8–10 years or more. Machines are constructed with durable steel components, quality motors, and wear-resistant parts to ensure longevity under continuous use.

Where are barbed wire machines most commonly used?

Applications include:

- Security fencing (military, prison, border areas)

- Agriculture (livestock fencing, crop protection)

- Highway and railway barriers

- Residential and commercial perimeters

- Forestry and wildlife area enclosures

These machines are widely used across industries requiring reliable, cost-effective perimeter control solutions.

Packing Details for Barbed Wire Machine

To ensure safe and secure transportation, each barbed wire machine is carefully packed using the following method:

1. Standard Export Wooden Case

- Material: Fumigation-free plywood case, reinforced with wooden frame.

- Structure: Heavy-duty pallet base with sealed side panels and top cover.

- Protection: Machine is fixed firmly to the base to prevent movement during transit.

2. Plastic Film Wrapping

- Purpose: Protects the machine from moisture, dust, and minor surface scratches.

- Application: Tight wrapping over all exposed surfaces, especially around moving parts and electrical components.

3. Internal Support & Cushioning barbed wire machines

- Securing Components: All detachable parts are either fixed on the base or packed separately in foam-padded boxes.

- Shock Absorption: Padding material is used inside the wooden crate to minimize vibration damage during handling.

4. Labeling and Handling Marks

- Exterior Labels: Includes shipping mark, model number, gross/net weight, and “Fragile” or “Handle With Care” signs.

- Compliance: Fully compliant with international shipping standards (ISPM 15) for wooden packaging.

Packing Dimensions (Approximate) barbed wire machines

- Main Machine Case Size: 1900 mm × 1300 mm × 1000 mm

- Gross Weight: Approximately 700–1000 kg depending on model and accessories

|

|