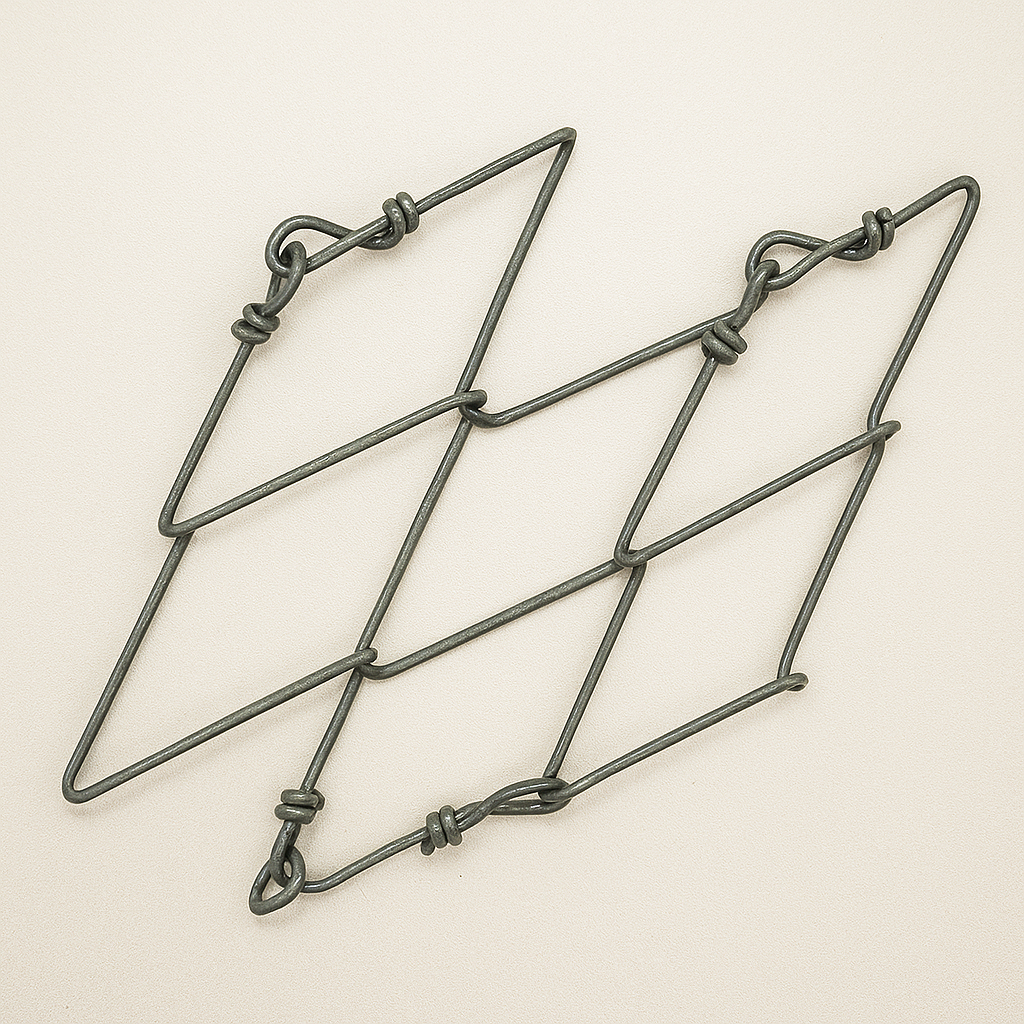

PVC Coated Wire Rope Net – 8mm Rope, 30×30cm Mesh

- Material: Steel wire rope

- Surface: Hot dipped galvanized + PVC coated

- Wire diameter: 8 mm

- Mesh size: 30 cm × 30 cm

- Chain mesh: 2.0–2.2 mm wire, 50 mm × 50 mm

- Supporting rope: 12 mm or 16 mm

- Sewing rope: 8 mm

- Anchor rod: 25 mm × 28 mm

- Anchor plate: 320 mm × 170/180 mm

- HS Code: 7314490000

- Price: USD 7.18–12.98/m²

Category:Product, RockFall Netting

Introduction

BMP’s PVC Coated Wire Rope Net provides tough, eco-friendly protection for mountains and slopes. With 8 mm galvanized steel ropes and PVC coating, this net system prevents landslides, rockfalls, debris flow, and more. BMP ensures high strength, corrosion resistance, and visual harmony with natural surroundings.

The active protection net system is a critical solution for maintaining slope stability and controlling rockfall. Primarily made from steel wire rope nets, this system is designed to be applied over slopes or rock faces. Its primary function is to limit weathering, peeling, and damage caused by natural forces such as erosion or rockfall. Additionally, the system provides reinforcement for preventing rockslides (reinforcement effect) and also helps contain and control the movement of falling rocks within a certain area (containment effect).

Materials Used in Active Protection Net Systems

The core materials used in the active protection net system include:

- PVC Coated Wire Rope Net: The net is made from durable steel wire ropes that provide high tensile strength, ideal for withstanding harsh environmental conditions.

- Ordinary steel wire mesh: Often referred to as wire mesh or steel grating, this is used in combination with the steel wire rope net for extra support in stabilizing the structure.

These materials work in tandem to provide long-lasting protection and resistance against external forces, making them highly effective for mountain and slope stabilization.

Construction and Installation of Active Protection Net

The construction of the active protection net system involves a flexible yet robust configuration of materials, ensuring maximum protection. There are two primary ways to fix the system to the slope or rock surface:

- Steel wire rope anchor rods and/or support ropes: These are the primary fixation methods for the steel wire rope net and steel wire mesh. The wire rope anchor rods secure the system to the mountain surface, while the support ropes provide additional reinforcement.

- Steel bars (with pre-stress capabilities) and steel wire rope anchor rods: For areas where edge support is necessary, steel bars may be used in conjunction with wire rope anchor rods to stabilize the net. Special anchor plates and, when necessary, edge support ropes, further enhance the strength and stability of the system.

This combination of materials and construction techniques ensures that the system can adapt to various environments and terrains, offering flexible and reliable protection against natural hazards.

Product Features and Benefits PVC Coated Wire Rope Net

The active protection net system works on principles similar to other protective systems such as shotcrete and soil nail walls, yet it stands out due to its flexibility. The system is designed to distribute localized concentrated loads evenly across the entire structure, making it highly effective for controlling large areas prone to rockslides and debris flow.

The benefits of the active protection net system include:

- High Load Capacity: The system can absorb significant loads from falling rocks and debris, making it suitable for high-risk areas.

- Reduced Anchor Load Requirements: Thanks to the even distribution of forces across the mesh, the system can handle greater overall loads while reducing the need for excessive anchoring force for each individual anchor rod.

- Environmental Compatibility: The flexible nature of the system allows it to blend seamlessly with the natural environment, providing protection without disturbing the surrounding landscape.

Simple Types of Active Protection PVC Coated Wire Rope Net

Active protection nets are available in various configurations to suit different types of slopes and terrain. A common example is:

-

Edge (or top) steel wire rope anchor rods + support ropes + sewing ropes: This configuration typically uses a D0/08/300 steel rope net, which is anchored at both the top and bottom edges, with additional support ropes running along the sides or horizontally to provide extra stability.

This simple yet highly effective design ensures that the system can adapt to a variety of environmental conditions, making it versatile and efficient.

Structure Configuration of Active Protection Net Systems

The active protection PVC Coated Wire Rope Net system is made up of several key components:

- Steel wire rope net: The primary protective material, providing strength and stability.

- Steel wire rope anchor rods: Essential for securing the system to the slope or rock face.

- Support ropes: Additional support to bear the load and provide extra stability to the entire system.

- Sewing ropes: Used for joining neighboring mesh sections, ensuring that the system works as a cohesive whole.

- Steel wire mesh: Often used in conjunction with the wire rope net to provide additional stabilization.

These components are carefully arranged and fixed to ensure that the system can withstand the natural forces that may act upon it.

Main Models of Active Protection Nets

There are several models of active protection nets, each designed to meet the specific requirements of different environments and applications. Some of the most common models include:

- GAR1

- GAR2

- GPS1

- GPS2

These models vary in terms of mesh size, rope thickness, and anchor configurations, allowing for customized solutions depending on the project’s needs.

PVC Coated Wire Rope Net for Enhanced Durability

In addition to the traditional materials used in active protection net systems, PVC-coated wire rope nets are becoming increasingly popular. These nets are coated with a layer of PVC, providing increased corrosion resistance and enhanced durability, especially in harsh weather conditions. The green PVC coating also improves the aesthetic integration of the system with the surrounding environment, making it a visually appealing solution for slope stabilization.

🔩 🔷 Key Components of BMP’s PVC Coated Wire Rope Net System

🟢 PVC Coated Wire Rope Net

- Made from hot-dip galvanized steel

- 8 mm wire diameter

- Mesh size: 30 cm × 30 cm

- Green PVC finish for weather protection

|

|

|

|

🧷 Chain Link Fence

- PVC coated galvanized wire

- Wire diameter: 2.0 mm or 2.2 mm

- Hole size: 50 mm × 50 mm

- Roll size: 2 m × 20 m

⚙️

- Anchor rod: 25 mm × 28 mm

- Bearing plate: 320 mm × 170 mm / 320 mm × 180 mm

- Supporting rope: 12 mm or 16 mm

- Sewing rope: 8 mm

📋 ✅ Complete Specifications Table (Original Size Maintained)

| Component | Specification |

|---|---|

| Material | Steel wire rope |

| Surface | Hot dipped galvanized + PVC coated |

| Zinc Coating Weight | ≥ 150 g/m² |

| Wire Diameter | 8 mm |

| Mesh Shape | Rhombus |

| Mesh Size | 30 cm × 30 cm |

| Roll Size | 4 m × 4 m / 4.5 m × 4.5 m |

| Chain Link Wire Diameter | 2.0 mm or 2.2 mm |

| Chain Link Mesh Size | 50 mm × 50 mm |

| Chain Link Roll Size | 2 m × 20 m |

| Anchor Diameter | 25 mm × 28 mm |

| Anchor Plate Size | 320 mm × 170 mm / 320 mm × 180 mm |

| Supporting Rope Diameter | 12 mm or 16 mm |

| Sewing Rope Diameter | 8 mm |

- HS Code: 7314490000

- Estimated Price: USD 7.18–12.98/m²

🌐 🏔️ Applications of PVC Coated Wire Rope Net

BMP’s PVC Coated Wire Rope Net fits various terrains:

- Used on slopes with soil, boulders, or loose rock

- Blocks landslides, debris flows, and snow avalanches

- Prevents rock collapse and falling stones

- Supports slope vegetation and natural blending

- Common on highways, mining zones, and steep cliffs

✅ 🌿 Benefits of BMP PVC Coated Wire Rope Net

- 💪 High Impact Resistance – Handles landslides and boulders

- 🌱 Eco-Friendly – Green PVC blends into the landscape

- 🔧 Corrosion Resistance – Zinc layer and PVC protect against rust

- 💚 Visual Appeal – Dulls harsh rock faces, enhances mountain appearance

- 🔄 Long Lifespan – Withstands harsh weather without damage

📦 📦 BMP Packaging & Delivery Details

- Shipped in rolls for easy handling

- Packed on wooden or steel pallets

- Labeled and sealed for weather resistance

- Delivery time: 7–15 days

- Minimum order: 500 m²

- Custom packaging on request

💬 📣 Customer Feedback from Qatar

“We installed BMP’s PVC coated net system near Doha’s southern cliffs. The net looks great, holds strong, and stops both large rocks and fine debris. It blends well into the green slope. Fast delivery and easy to set up too.”

— Project Supervisor, Geological Safety Dept., Qatar

🧠 🔍 FAQs – BMP’s PVC Coated Wire Rope Net

Q: Can this net handle heavy rockfalls?

A: Yes. The 8 mm PVC coated rope is strong and designed to absorb high impact.

Q: Will it rust or fade over time?

A: No. The zinc layer plus PVC coating ensures lasting durability.

Q: Is it suitable for wet, snowy zones?

A: Absolutely. It performs well in snow, rain, and coastal areas.

Q: Can I cut the net to fit special shapes?

A: Yes. It’s flexible and can be customized on-site.

📌 ⚠️ Conditions to Consider PVC Coated Wire Rope Net

- Ensure correct anchor depth for soil type

- Use proper tension tools during setup

- Choose chain link addition for fine rock areas

- Confirm site access for palletized delivery

- Match rope size to slope’s hazard level

🏁 🔚 Conclusion: BMP’s PVC Coated Wire Rope Net – Slope Safety in Style

BMP’s PVC Coated Wire Rope Net brings safety, durability, and aesthetics together. From Qatar’s dry zones to alpine hills, it guards slopes, secures roads, and beautifies landscapes. Count on BMP for advanced slope protection that lasts.