Introduction

Spider Spiral Rope Mesh is a high-performance solution designed for stabilizing slopes, especially in rocky and unstable terrain. With its 1770 N/m² tensile strength and durable galvanized coating, this mesh system provides reliable protection against rockfalls, debris flow, and landslides. Used in challenging environments, Spider Spiral Rope Mesh ensures long-term safety while supporting vegetation growth on slopes.

The SPIDER High-Strength Rope Mesh Protection System is a new active protection method that uses high-strength steel rope mesh panels as the main component. It is a high-quality slope protection product for reinforcing steep rock slopes, isolated rocks, and loose hazardous rocks.

SPIDER High-Strength Rope Mesh Technical Parameters:

- Main Models: GSS2A and GSR2A.

- Main Components: High-strength steel rope spiral mesh + prestressed steel anchor rods + special anchor base plates + support ropes + stitching ropes.

- Fixing Method: Fastened with prestressed steel anchor rods and special anchor base plates.

- Load Capacity: Currently, all flexible slope stabilization systems are considered.

- Applicable Range: Overall stabilization and reinforcement of soil and rock slopes, reinforcement of isolated rocks and hazardous rocks, and can also be combined with deep-layer consolidation measures for landslide treatment.

-

SPIDER High-Strength Rope Mesh Protection System:

- (1) Breakage Tension: 195-220 KN/M

- (2) Mesh Wire Diameter: 3.0mm

- (3) Mesh Hole Size: 292X500mm (±5%)

- (4) Strand Structure: 1X3

- (5) Wire Tensile Strength: Not less than 1770N/mm²

- (6) Coating Weight: Not less than 150g/m²

- (7) Compared to Traditional Steel Rope Mesh Systems: Simple components, more efficient installation. The new structural design theory, the selection of anchor rod types, and their arrangement are more targeted. The special mesh and anchoring methods create greater pre-stress on the slope and better system force transfer. The system has a longer corrosion resistance lifespan.

Our products mainly include: Slope protection nets, active protection nets, passive protection nets, RX-075 model passive protection nets, RX-050 model passive protection nets, flexible protection nets, high-strength grid nets, Titan nets, passive ring nets, RXI-050 model ring nets, Brookes nets, steel rope nets, hot-dip galvanized steel rope anchor rods, etc.

SPIDER Rope Mesh is a crucial keyword in understanding this advanced and efficient slope protection technology.

🧷 📐 Components of Spider Spiral Rope Mesh System

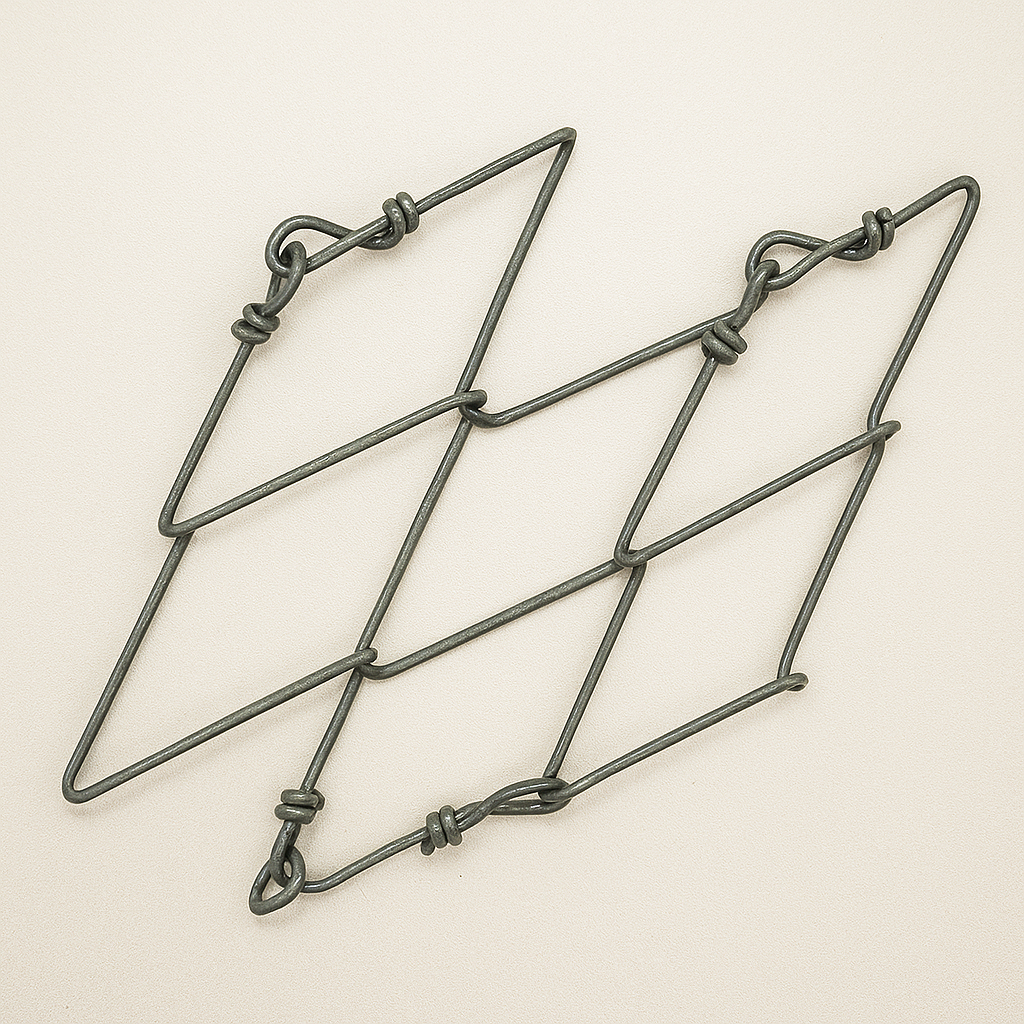

🪢 Spider Spiral Rope Mesh

- Made of high-tensile spring wire for maximum strength.

- Mesh size: 250 mm – 300 mm inner circle diameter.

- 1770 N/m² tensile strength ensures superior load capacity.

🪝 Chain Link Mesh

- 2.2 mm wire diameter with 50 mm mesh size.

- Hot-dip galvanized for excellent corrosion resistance.

🪛 Prestressed Anchor

- Reinforcing steel bar anchor for stability.

- Diameter: 25 mm or 28 mm with threaded ends.

🔩 Anchor Plate

- Claw-type design for secure attachment to slopes.

- Plate size: 320 mm × 180 mm, thickness: ≥10 mm.

🪢 Boundary and Sewing Ropes

- 14 mm – 16 mm diameter steel wire ropes.

- Used to enclose and connect mesh sections for added stability.

📋 ✅ Complete Specifications Table (Original Size Maintained)

| Component |

Specification |

| Wire Diameter |

3.0 mm |

| Strands |

3 strands |

| Mesh Size |

Inner circle diameter: 250 mm – 300 mm |

| Tensile Strength |

1770 N/m² |

| Zinc Coating Weight |

150 g/m² |

| Roll Width |

3.5 m |

| Roll Length |

10 m or 30 m |

- HS Code: 73144900

- Price: USD 5.50–8.00/m²

🌐 🏔️ Applications of Spider Spiral Rope Mesh

Spider Spiral Rope Mesh is versatile and effective in various applications:

- Slope stabilization in high and steep rocky terrains.

- Mountain protection from rockslides and debris flows.

- Road protection against falling rocks and soil erosion.

- Vegetation protection by allowing plants to grow through mesh gaps.

🌟 💡 Benefits of Spider Spiral Rope Mesh

- 💪 High Tensile Strength: Withstands the impact of landslides and debris flow.

- 🌱 Environmentally Friendly: Allows grass and plants to grow, blending with the landscape.

- 🌧️ Corrosion Resistance: Hot-dip galvanized for lasting durability in harsh conditions.

- 🛡️ Long Service Life: Designed to provide 100+ years of protection with minimal maintenance.

📦 📦 Packaging & Delivery from BMP

- Packaging: Rolls secured for easy handling.

- Roll Size: 3.5 m width, 10 m – 30 m length.

- Lead Time: 7–15 days depending on order size.

- Minimum Order: 500 m²

💬 📣 Customer Feedback from Qatar Spider Spiral Rope Mesh

“We used Spider Spiral Rope Mesh in a road stabilization project in Qatar. It’s easy to install, highly durable, and effectively prevents rockfall. The mesh has blended well with the environment, and we’ve seen significant improvements in slope safety.”

— Civil Engineer, Qatar Infrastructure Project

🧠 🔍 FAQs

Q: What is the tensile strength of the Spider Spiral Rope Mesh?

A: The mesh has a 1770 N/m² tensile strength, ensuring it can withstand high impacts.

Q: Is it suitable for high-slope terrains?

A: Yes, it’s specifically designed for high and steep rock surfaces.

Q: Can this mesh be used in all weather conditions?

A: Yes, the corrosion-resistant coating ensures durability in various weather conditions.

📌 ⚠️ Conditions to Consider When Using Spider Spiral Rope Mesh

- Site Preparation: Ensure proper anchoring for effective slope stabilization.

- Mesh Tensioning: Proper tension is required for optimal system performance.

- Environmental Considerations: Ensure the mesh doesn’t interfere with local ecosystems.

🧾 📌 Summary of Spider Spiral Rope Mesh Specifications

- Wire Diameter: 3.0 mm

- Tensile Strength: 1770 N/m²

- Zinc Coating: 150 g/m²

- Roll Size: 3.5 m wide, 10 m – 30 m long

- HS Code: 73144900

- Price: USD 5.50–8.00/m²

🏁 🔚 Conclusion: Spider Spiral Rope Mesh for Long-Lasting Rockfall Protection

Spider Spiral Rope Mesh is a reliable, flexible, and durable solution for slope and rockfall protection. Whether you’re protecting roads, slopes, or mountains, this mesh system’s high tensile strength, corrosion resistance, and environmental compatibility ensure long-term safety and performance.

Inquiry